21 Sep 2016 Eastern Interceptor – Sewpercoat

Completed in 1962, the Eastern Interceptor is a large-diameter, reinforced-concrete wastewater pipe that follows a 19km path from Auckland’s Okahu Bay to the Mangere Wastewater Treatment Plant. It’s a vital part of the city’s wastewater management system, carrying about two-thirds of its wastewater and acting as the main collection point for many large and small sewers.

For this reason, Watercare – the company that provides water and wastewater services to the Auckland region – maintains a rigorous monitoring, maintenance and, where necessary, repair programme. BBR Contech was most recently involved in 2005, when we repaired several sections in what was thought to be the first large-scale remedial concrete works to be carried out in a fully live, man-entry sewer in New Zealand.

We’ve recently been called on again, this time to remove and replace damaged concrete in two other parts of this critical element of Auckland’s infrastructure – one a 205m-long section at the wastewater plant itself, and the other a 440m-long section in Mt Wellington. The latter is posing some particularly complex challenges for the team, as it’s located in a heavily populated residential area that includes a primary school. This has required us to take a scrupulous approach to planning and implementing the project, and to keeping the affected community informed along the way.

A meticulous approach

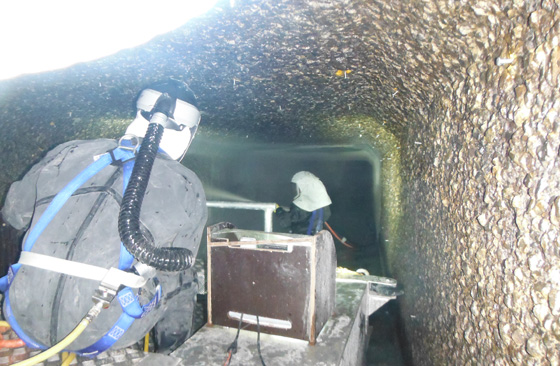

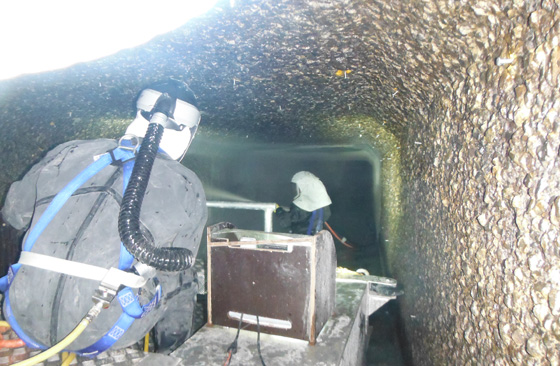

Work like this is never pleasant for the BBR Contech team, with a hazardous working environment in which everyone is required to follow stringent health and safety policies. These include wearing dry suits equipped with adequate supplies of fresh air, and maintaining a strict limit on the time spent in the underground pipe environment. In Mt Wellington, the team also has to work overnight, with a constant focus on minimising noise and other disruptions to the residents nearby.

Spread over two stages and due for completion in mid-2014, the project involves:

- preparing the surface using robotic high-pressure water blasting, which is very effective in removing the affected concrete without disturbing raw sewage

- applying 350 tonnes of Kerneos SewperCoat® – a technologically sophisticated calcium aluminate product that’s sprayed on to provide highly effective, high-strength, corrosion-resistant protection against biogenic sulphide corrosion.

While those working on the project will no doubt be relieved to see it completed, they can be very proud of their role in helping to ensure that Auckland’s wastewater system continues to perform well into the future.

Kerneos SewperCoat® is ideally suited to sewer repair and addresses the effects of biogenic sulphide corrosion – a bacterial process that attacks concrete and steel in these environments.